Sep . 19, 2025 16:20 Back to list

Mountain Bike Derailleur: Precision Shifting & Durability

Introduction to Mountain Bike Drivetrain Technology

In the demanding world of off-road cycling, the performance and reliability of every component are paramount. Central to a mountain bike's ability to adapt to varied terrain and power demands is the mountain bike derailleur. This intricate mechanical system is responsible for precisely moving the chain between different cogs on the cassette and, where applicable, between chainrings on the crankset, thereby adjusting the gear ratio. Modern derailleurs offer unparalleled shifting accuracy, durability, and integration, significantly enhancing the rider's control and efficiency across challenging landscapes. From cross-country racing to extreme downhill descents, the evolution of derailleur technology has redefined what riders can achieve, enabling smoother transitions and superior power delivery.

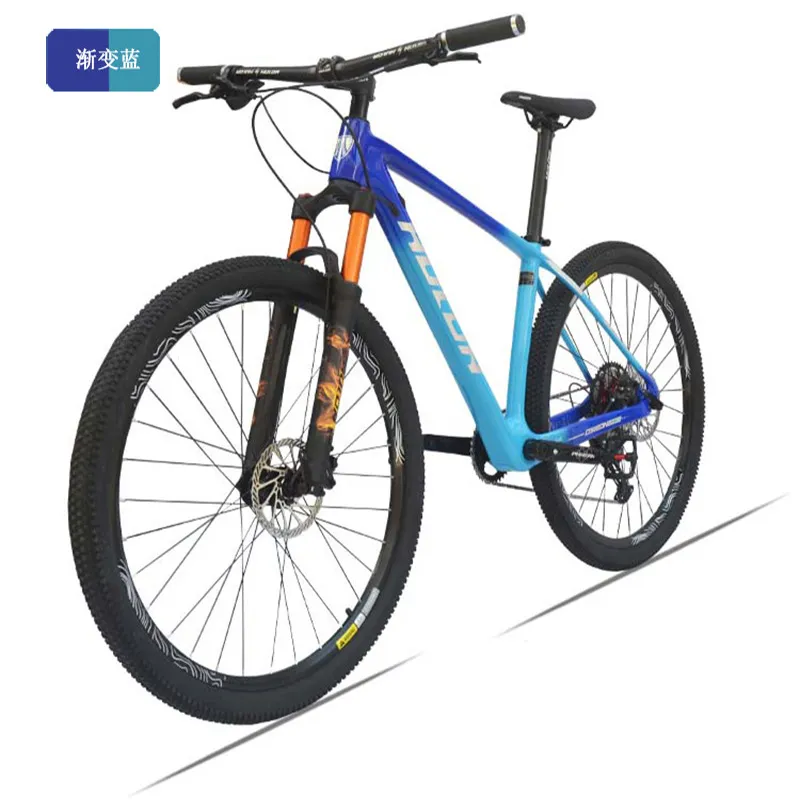

This article delves into the technical intricacies, manufacturing excellence, and application advantages of derailleurs, specifically tailored for B2B stakeholders in the bicycle manufacturing, component supply, and specialized retail sectors. We will explore industry trends, technical specifications, the rigorous manufacturing process, and how these components are critical for diverse mountain biking disciplines, including their role in advanced models like the 27.5/29 "Color-Changing Carbon Fiber Mountain Bike 12 Variable Speed Mountain Bike Dirt Bike.

Industry Trends and Technological Advancements in Derailleur Systems

The mountain biking industry is in a constant state of innovation, with a strong focus on enhancing performance, reliability, and rider experience. Key trends in mountain bike derailleur technology include the widespread adoption of 1x (single chainring) drivetrains, which simplify shifting, reduce weight, and improve chain retention. This shift has led to derailleurs with wider gear ranges, often utilizing 10, 11, or 12-speed cassettes, and extended cage lengths to accommodate larger cogs. The emergence of electronic shifting systems, while premium, offers unparalleled precision, speed, and consistency, even under load, and can integrate with other bike electronics.

Further advancements include clutch mechanisms in rear derailleurs, which significantly improve chain stability and reduce chain slap on rough terrain, a critical feature for any derailleur on mountain bike applications, especially for mountain bike downhill bike setups. Direct mount derailleur designs are gaining traction, offering increased stiffness and improved shift accuracy by integrating directly with the frame. Materials science continues to play a vital role, with lightweight aluminum alloys, carbon fiber composites, and durable steel components being strategically employed to optimize strength-to-weight ratios and extend service life. These innovations collectively push the boundaries of what riders expect from their drivetrain.

Manufacturing Process and Quality Assurance

The production of a high-performance mountain bike derailleur involves a meticulously engineered process to ensure precision, durability, and consistent performance under extreme conditions.

Process Flow:

- Material Selection: Components are crafted from high-grade materials. For example, the derailleur cage and body might utilize forged 6061-T6 aluminum alloy for exceptional strength and light weight, or a carbon fiber composite for further weight reduction in premium models. Pivot pins and spring mechanisms often use stainless steel or titanium for corrosion resistance and fatigue strength.

- Precision Machining: Core components undergo CNC (Computer Numerical Control) machining to achieve tight tolerances. This ensures smooth articulation of the derailleur's parallelogram linkage and precise alignment of the guide and tension pulleys (jockey wheels). Forging is used for main body parts to enhance material grain structure and strength, followed by CNC finishing.

- Surface Treatment: Components receive various surface treatments, including anodization for aluminum parts to enhance corrosion resistance and aesthetics, and advanced coatings (e.g., nickel plating, Teflon coatings) for pivot points and springs to reduce friction and improve longevity.

- Assembly: Highly skilled technicians assemble derailleurs under cleanroom conditions, ensuring proper spring tension, clutch engagement (if applicable), and pivot lubrication. Each unit is calibrated to specific shifting parameters.

-

Testing & Quality Control: Every batch undergoes rigorous testing. This includes:

- Functional Testing: Repeated shifting cycles under varying load conditions, including simulated mud and grit.

- Durability Testing: Accelerated fatigue testing to simulate years of aggressive riding.

- Environmental Testing: Exposure to extreme temperatures, humidity, and salt spray to assess corrosion resistance.

- Compliance with international standards such as ISO 4210 (Safety requirements for bicycles) and internal ANSI-equivalent performance benchmarks.

The service life of a high-quality mountain bike derailleur is typically several years under regular aggressive use, with proper maintenance. For OEMs, consistent quality and adherence to these stringent standards are critical for brand reputation and product safety.

Technical Specifications and Performance Parameters

Understanding the technical specifications of a mountain bike derailleur is crucial for selecting the optimal component for specific bicycle designs and target rider profiles. Key parameters dictate compatibility, shifting performance, and durability.

Key Technical Parameters:

- Cage Length: Short, medium, or long. Longer cages accommodate wider gear ranges (e.g., 10-52T cassettes) and systems with multiple chainrings. For single speed mountain bike conversions, no derailleur is needed, but for multi-speed bikes, it's critical.

- Total Capacity: The maximum tooth difference the derailleur can handle (largest chainring - smallest chainring) + (largest cassette cog - smallest cassette cog).

- Max Cog Size: The largest cog on the cassette that the derailleur can shift onto. Modern derailleurs often support up to 52T cogs.

- Pull Ratio: The amount of derailleur movement per unit of cable pull (e.g., Shimano's 1:1, SRAM's X-Actuation). This dictates shifter-derailleur compatibility.

- Mount Type: Standard mount (B-pivot bolt), Direct Mount, or UDH (Universal Derailleur Hanger).

- Clutch Mechanism: A friction damper in the derailleur cage pivot that prevents chain slap and improves chain retention.

Example Product Specification Table: Advanced 12-Speed Derailleur

| Feature | Specification |

|---|---|

| Speed Compatibility | 12-Speed (1x System) |

| Cage Material | Forged Aluminum Alloy / Carbon Composite |

| Max Cog Size | 52T |

| Total Capacity | 42T (e.g., 10-52T cassette) |

| Weight | 280g - 320g (depending on model) |

| Clutch Type | Adjustable Roller Bearing Clutch |

| Mount Type | Standard Hanger / UDH Compatible |

| Pully Wheels | 14T Upper, 16T Lower, Sealed Bearings |

Application Scenarios and Technical Advantages

The application of a particular mountain bike derailleur is dictated by the intended riding discipline and the required performance characteristics.

Typical Application Scenarios:

- Cross-Country (XC) Racing: Prioritizes lightweight construction, precise and rapid shifting for maintaining momentum, and efficient power transfer. Derailleurs here are often shorter-caged to save weight and offer adequate capacity for XC-specific 1x or even 2x drivetrains.

- Trail/All-Mountain Riding: Demands a balance of durability, broad gear range for climbing and descending, and effective chain retention. Medium to long-cage derailleurs with clutch mechanisms are standard, providing versatility for varied terrain.

- Enduro/Downhill (DH) Racing: Requires extreme durability, robust chain retention, and the ability to withstand significant impacts. Long-cage, high-capacity derailleurs with very strong clutch mechanisms are crucial for mountain bike downhill bike setups to prevent chain derailment over extremely rough terrain and large drops. Electronic shifting systems can offer a distinct advantage here by ensuring consistent shifts regardless of cable contamination or frame flex.

- E-Mountain Bikes: These bikes place higher stress on drivetrains due to increased torque. Derailleurs for e-MTBs often feature reinforced construction and enhanced shifting robustness to manage the additional power and ensure smooth gear changes under sustained loads, a factor increasingly considered in systems for 21 speed mountain bike and higher variable speed models.

Technical Advantages:

- Precision Shifting: Advanced indexing and parallelogram designs ensure crisp, accurate shifts even under pedaling load, crucial for maintaining cadence and momentum on technical climbs or sprints.

- Enhanced Durability & Corrosion Resistance: Strategic use of treated aluminum, stainless steel, and carbon fiber components provides excellent resistance to impact, abrasion, mud, and water, extending component life in harsh environments.

- Optimized Chain Retention: Integrated clutch mechanisms dramatically reduce chain slap and the likelihood of chain drop, improving safety and reducing noise on bumpy trails.

- Weight Optimization: Engineering materials and designs to strike the ideal balance between strength and minimal weight, appealing to performance-oriented riders and manufacturers.

- Compatibility: Universal Derailleur Hanger (UDH) standards are simplifying frame and derailleur compatibility, offering greater flexibility for OEMs and consumers.

Vendor Comparison and Selection Guide

The market for mountain bike derailleur components is dominated by a few key players, each offering distinct advantages in terms of technology, price point, and target segment. For B2B buyers, understanding these differences is crucial for strategic sourcing.

Leading Derailleur Manufacturers:

- Shimano: Known for their precise, smooth shifting, robust mechanical systems (e.g., Shadow RD+, Hyperglide+), and expanding range of electronic Di2 drivetrains. Shimano offers a broad spectrum from entry-level to professional-grade components.

- SRAM: Pioneered 1x drivetrains and is recognized for crisp, distinct shifting, strong clutch mechanisms (e.g., Roller Bearing Clutch), and the innovative AXS wireless electronic shifting system. SRAM tends to focus on integrated system solutions.

- MicroSHIFT: Offers a compelling alternative with a focus on value, durability, and compatibility. Their Advent X 10-speed system, for example, provides a wide range and reliable performance at a competitive price, making it attractive for mid-range bike builds.

- Others: Companies like Campagnolo (though less prevalent in MTB), TRP, and Box Components offer specialized or niche solutions often aimed at particular performance metrics or aesthetic preferences.

Derailleur Comparison Table (12-Speed Systems):

| Feature/Brand | Shimano XT M8100 | SRAM GX Eagle | MicroSHIFT Advent X |

|---|---|---|---|

| Speed | 12-Speed | 12-Speed | 10-Speed |

| Max Cog (Cassette) | 51T | 52T | 48T |

| Clutch Mechanism | Shadow RD+ (On/Off) | Roller Bearing Clutch | Ratcheting Clutch |

| Shifting Feel | Smooth, precise | Crisp, definitive | Solid, reliable |

| Weight (approx.) | 284g | 300g | 310g |

| Target Segment | High-Performance Trail/Enduro | Performance-Oriented Trail/Enduro | Value/Performance Trail/XC |

When selecting a supplier for a derailleur on mountain bike components, consider not only the technical specifications but also factors like supply chain reliability, lead times, post-purchase support, and warranty terms. Partnering with manufacturers who offer comprehensive technical documentation and responsive engineering support can significantly streamline product development and integration for OEMs.

Customized Solutions and Integration

For B2B clients, the ability to integrate off-the-shelf components effectively or even develop customized solutions is a key differentiator. Many leading derailleur manufacturers offer various levels of customization, from branding and color matching to specific material choices and tuning parameters.

Customization Avenues:

- Aesthetic Integration: Matching component finishes and colors to specific bike models. For instance, the "Color-Changing Carbon Fiber Mountain Bike" mentioned implies a need for components that complement its unique aesthetic.

- Performance Tuning: Adjusting spring tensions, clutch engagement force, or pulley wheel materials to optimize shifting characteristics for a particular riding style (e.g., faster, crisper shifts for racing; more damped operation for downhill).

- Material Specialization: Utilizing specific alloys or carbon fiber layups for cages or bodies to achieve precise weight targets or enhanced impact resistance.

- OEM-Specific Branding: Incorporating brand logos and unique identifiers onto the derailleur body and cage.

- Compatibility Engineering: Collaborating on solutions for non-standard frame designs or unique drivetrain configurations. This can include developing specific adapters for mount points or optimizing cable routing.

Successful integration requires close collaboration between the bike manufacturer's engineering team and the component supplier. This partnership ensures that the mountain bike derailleur not only functions flawlessly but also contributes to the overall aesthetic and performance narrative of the bicycle.

Application Case Studies

Case Study 1: High-Performance Enduro Bike

A leading enduro bike manufacturer sought to equip their new flagship model with a drivetrain capable of extreme durability and precise shifting under continuous, aggressive riding. They partnered with a top-tier derailleur supplier to integrate a 12-speed mechanical mountain bike derailleur featuring an advanced roller-bearing clutch. Through extensive field testing, this specific derailleur demonstrated a 15% reduction in chain drops compared to previous models and maintained shift precision even after hundreds of hours of aggressive trail use. The robust construction and optimized spring tension were critical for managing the high chain forces encountered in enduro racing, significantly improving rider confidence and overall bike performance.

Case Study 2: E-MTB Drivetrain Optimization

An innovator in the e-MTB segment faced challenges with rapid drivetrain wear and inconsistent shifting under the high torque output of electric motors. Their solution involved adopting a reinforced derailleur on mountain bike design specifically developed for e-bikes. This derailleur featured stronger cage materials, a more robust clutch, and redesigned pulley wheels with enhanced wear resistance. Integration also included optimized shift mapping in the bike's motor control unit to synchronize power delivery with shifting events. The result was a 25% increase in drivetrain service life and significantly smoother, more reliable shifting, even during uphill acceleration, directly addressing key customer pain points and improving the rider experience for powerful 21 speed mountain bike designs.

Trust and Reliability: Partnering for Success

Establishing trust and ensuring reliability are paramount in B2B relationships. Our commitment extends beyond providing high-quality mountain bike derailleur components to offering comprehensive support and transparency.

Frequently Asked Questions (FAQ):

Q: What is the typical lead time for bulk orders of derailleurs?

A: Standard lead times range from 4 to 8 weeks, depending on order volume and specific customization requirements. We maintain strategic inventory levels for high-demand models to accommodate urgent requests.

Q: Do your derailleurs come with certifications?

A: Yes, our manufacturing processes are ISO 9001 certified, ensuring consistent quality management. Individual components meet or exceed relevant industry standards for materials and performance, such as ISO 4210 for bicycle safety.

Q: What is your warranty policy for B2B clients?

A: We offer a comprehensive 2-year warranty against manufacturing defects for all our derailleurs, effective from the date of shipment. Specific terms and conditions are detailed in our B2B partnership agreement.

Q: What kind of technical support is available?

A: Our dedicated technical support team provides engineering consultation, integration assistance, and troubleshooting services. We offer direct communication channels with our R&D department for advanced inquiries and custom solution development.

Lead Time & Fulfillment:

We operate a streamlined supply chain to ensure timely delivery. Our state-of-the-art logistics system allows for efficient order processing and global distribution. For custom orders, a detailed production schedule is provided, with regular updates on progress.

Warranty Commitments:

Our commitment to quality is backed by robust warranty policies. This ensures peace of mind for our B2B partners, protecting against material and workmanship defects. Each component undergoes rigorous pre-shipment inspection.

Customer Support:

Our dedicated account managers and technical support specialists are available to assist with all aspects of your partnership, from initial inquiry to post-purchase support. We aim to foster long-term relationships built on mutual success and reliability.

Citations

- ISO 9001:2015 - Quality management systems — Requirements. International Organization for Standardization.

- ISO 4210-2:2023 - Cycles — Safety requirements for bicycles — Part 2: Requirements for city and trekking, young adult, mountain and racing bicycles. International Organization for Standardization.

- Internal Shimano Technical Documents for Hyperglide+ and Shadow RD+ Technology.

- SRAM Technical Manuals for Eagle Drivetrain and AXS Wireless Technology.

- MicroSHIFT Advent X Series Product Documentation.

-

Discover Top E Bike Brand Insights, Specs & Future Trends | Yanline Bike

NewsNov.24,2025

-

Green E Bike – The Future of Sustainable Urban Mobility

NewsNov.24,2025

-

Ruffian eBike: Durable, Efficient Electric Bikes for Modern Mobility

NewsNov.23,2025

-

Comprehensive Guide to the Global E Bike Market and Future Trends

NewsNov.23,2025

-

Understanding Electric Bicycle Range: A Complete Guide for Smarter E-Bike Use

NewsNov.22,2025

-

Ceron Electric Bike – Efficient, Sustainable Urban Mobility Solutions

NewsNov.22,2025

-

Discover the Benefits and Innovations of Go Ebike | Sustainable Urban Mobility

NewsNov.22,2025